Individual Guide On Online Steel Supplier

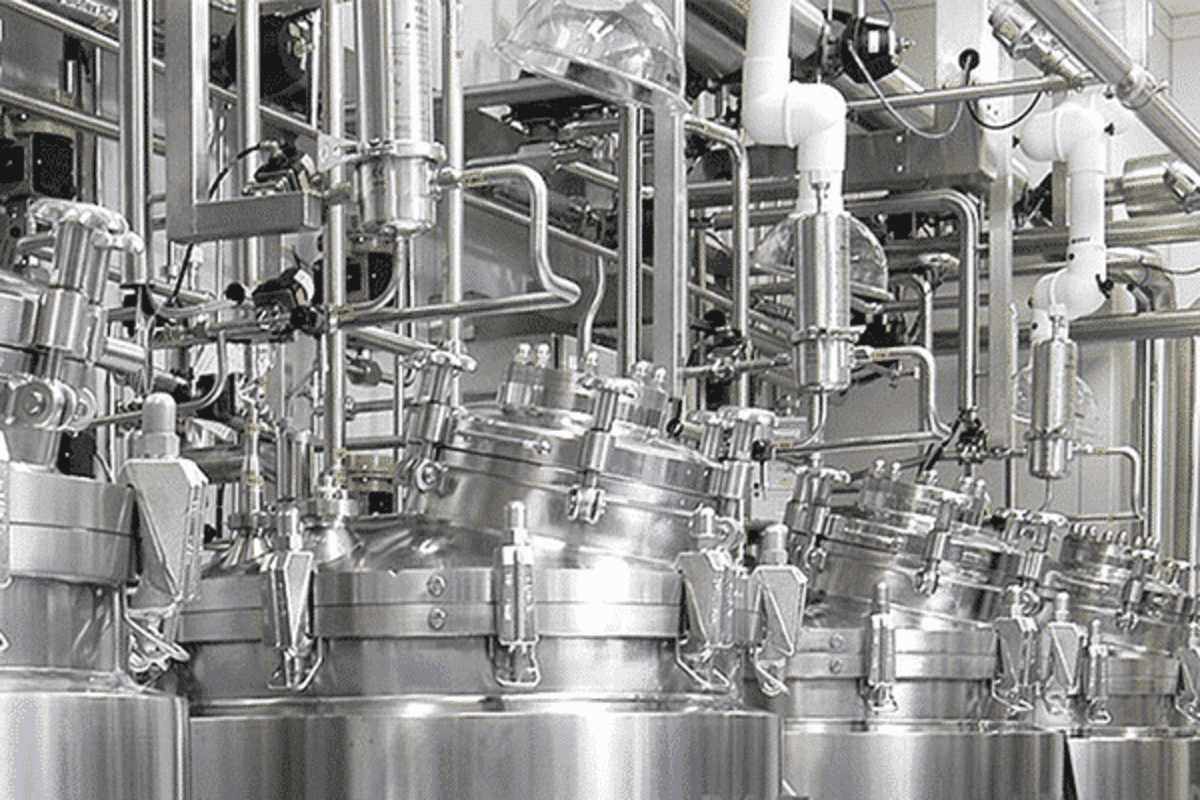

Suppliers and contractors are the backbones of most businesses. They add agility and quality to the business. They not only provide the raw material and ancillaries but can also help you determine your competitiveness, technology changes, market conditions, and new product development. The steel industry has been the backbone of machines since industrialisation. It is hard to imagine our life without steel. There are many types of steel that can be used in the construction of small tools and big finished machines. The steel used by these machines is the same as that of their suppliers. It can be hard to find a reliable supplier. Shrewd customers always place quality as their top priority. But quality comes with a price. Steel suppliers often get chosen for their low prices. A win-win business relationship is desirable. Machine manufacturers must evaluate the quality policies and technical capabilities of steel suppliers to maintain the same quality for every order. It is also important to check the existing client portfolios of suppliers and determine the quality of their steel. This is the most important thing that will make a relationship with a manufacturer-vendor partner lasting. The carbon content of steel is a measure of its quality. There are many tools and methods that can be used to assess steel quality.

A well-respected and established steel company will have a track record of high customer satisfaction. Talking to the top management will give you more information about their credibility. Steel suppliers with more years in business also understand and fulfill manufacturer requirements. You can get a good idea of the vendor’s credibility by speaking to an existing customer. Trust is essential for any business relationship. Good relationships are built on trust and reliability. Reliable steel suppliers will work with the Just in Time (JIT) philosophy. They will deliver exactly what you ordered in the shortest time possible and maintain pristine quality. It also lowers the cost for storage and handling at manufacturers’ end. There are more uncertainties than ever in the steel sector. The technology cycle is one of the most rapid in recent history. To be able to respond to changes in the market, it is essential that the vendor has agility. If you are looking for more information on https://www.steelproductsdirect.com/, view the earlier mentioned site.

It is important for suppliers to be flexible when responding to new opportunities, new technology, new strategies and changes in the law and market requirements. Agility can also be used to reduce lead time in the manufacturing setting. Competitiveness is a comparative concept of the ability and performance of a firm, sub-sector or country to sell and supply goods and services in a given market. It is the best indicator of whether the business relationship will last longer or end in a few years. The steel supplier may be able to adapt to changes but can they deliver the product at the exact same price or at a lower rate? Can the vendor retain the same quality but keep its agility, credibility and reliability? Supplier competitiveness is often driven by original equipment manufacturers (OEM). Maintaining a good relationship with a supplier is as important as choosing one. Once you’ve established a rapport with your supplier, it’s a good idea to work with them and not for them.